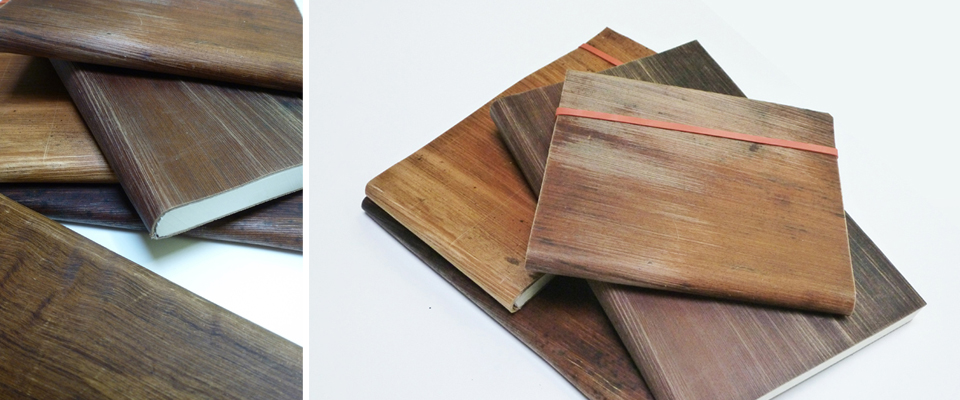

PalmLeather

What it is

Palmleather is made by dipping the dry and brittle leave from the Arecae Betel Nut into a biological softening solution we’ve designed in 2011. After a few days the material turns permanently soft and flexible and shows great aesthetic quality. The material can be processed on conventional machines.

Replacing leather

The entire Palmleather project was instigated as a cheap plant based replacement for animal leather, plastic and rubber. These materials are sustainable nightmares and hit even harder in the poorer regions of the world.

Utilizing waste streams

Waste does not exist. But in general food-production brings large volumes of waste, pre-consumption and after consumption. Before returning to the natural compost cycle the Areca Betel Nut leaves can be upgraded to become more useful. Key is not to pollute this waste material when upgraded.

Natural material upgrade

Natural fibers are under appreciated and have (to) little value. Increasing there versatility and functionality greatly contributes to natural fibers becoming used more frequent again. By upgrading natural fibers used in craft sustainable change can be a bottom up process.

Ecological solution

This mixture has no harmful effect on people, animal or nature, on a small or large scale. All ingredients are graded for human consumption. The compounds are easily absorbed in the local biotope.

Raw material availability

Small processes grow and it is important to look ahead from the start. In the Southern part of India 80 million Areca Betel Nut trees grow in plantations, parks, reserves and in natural habitat. Modest estimates result in 1 m2 leave material from 1 tree of which at this moment 5% is utilized with the production of Areca Leave Plates.

Water consumption

In leather, cotton and wool large quantities of water is being used. It is also hard to use this water in closed production cycles because cleaning the water for re-use is to expensive. Jeans use up to 1200 liter of water in the production process. Palmleather strives to use a maximum of 20 liter per m2 Palmleather premium quality in this process.

Date

2011 -